Nortek Air Solutions’ FANWALL EC is a complete, integrated fan system that is mounted to a bulkhead wall instead of being built from individual fan cells into an array like traditional FANWALL units.

Construction

FANWALL EC is built tough for optimum strength and stability:

- All the structure’s exterior joints are welded together for added strength.

- Interior panels are constructed of galvanized steel with motor mounts in a heavier gauge for support.

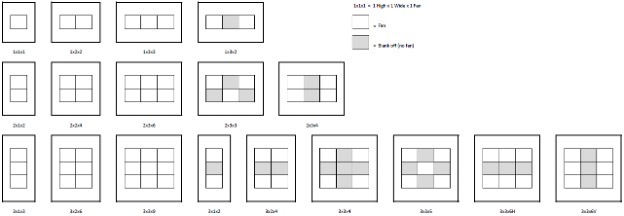

Configurations

The wall can be configured as one fan, or multiple fans arranged in-line or in different locations to provide more evenly distributed air across the wall.

Up to nine fans can be installed in a single 3 x 3 grid, and multiple grids can be added along the bulkhead wall to provide more airflow as needed.

Benefits:

- Flexible configuration

- Easy installation

- Rugged construction

- Low maintenance

- Reliable

- Small footprint

- Efficient

- Low sound levels

- Simple operation

- AMCA certified wheels

- ETL listed

Solve Air Handling Challenges

- 12-18” reduction in required airway length, requiring less space in a mechanical room

- 20-25% weight reduction on FANWALL sections, requiring less field structural support

- Cost-effective solution

- Energy efficient ECMi motor combines superior part-load efficiency with a built in VFD

- AMCA 204 Balance Tolerance – BV4

- Optimized selections up to 7" TSP

Simple Operation, Reliable, and Low Maintenance

- Simple Operation: FANWALL EC is easy to operate with a standard analog control interface and an optional DCC controls package with available features like BACnet® compatibility.

- Reliable: Because FANWALL EC is made up of an array of fans, if one fan fails, the remaining fans can automatically ramp up to maintain airflow until the fan can be replaced.

- Low-Maintenance: There are no belts, sheaves, or greasing required, making them virtually maintenance-free.

Contact us for more information. We’re ready to help with your next project!